What Is The Amp Draw On 2016 Power Pole Pump

Types of aerators, fuels and electric motors

Mechanical aeration is a major component of energy use in shrimp farming. Around 4 meg metric tons (MT) of the roughly 5 million MT of farm-reared penaeid shrimp in 2016 were from mechanically aerated ponds. The corporeality of aeration used in shrimp ponds has not been carefully studied, simply shrimp farm managers often use a "dominion of thumb" that each 300- to 500-kg increment of shrimp production requires ane hp of aeration (3.33 to 2.0 hp/MT shrimp). Upward to ane.5 MT/ha of shrimp tin can be produced without aeration, but this quantity usually is not subtracted from the production goal in calculating aeration charge per unit in social club to allow a safety gene.

Determination of aeration rate from practical experience is not exact, merely the complication of dissolved oxygen budgets in aquaculture ponds makes it impossible to accurately calculate the aeration rate using equations based on hourly oxygen demand of the h2o, aerator oxygen transfer efficiency, minimum acceptable dissolved oxygen concentration, and h2o quality characteristics as done for wastewater treatment basins. Practical feel and monitoring of dissolved oxygen concentration remain the common ways of deciding how much aerator horsepower to install in ponds and for establishing schedules for daily aerator operation.

Small, electrical motors use about 1 kWhr (a kilowatt hour is a unit of measurement of energy equal to 3.6 megajoules) electricity per horsepower-hour of operation. The amount of energy used per MT of shrimp at an aeration rate of 2.5 hp/MT shrimp with aerators operated in ponds for an average of 16 hours a day during an 80-day grow-out period is quite large. Amounts of electricity (and free energy) per hectare volition increase steadily every bit product goal in MT per hectare increases, but the amount of energy practical per MT of shrimp for aeration is 11.5 GJ/MT (2.5 kW/MT ×16 hours/solar day × eighty days/ingather × 0.0036 GJ/kWhr; GJ = gigajoule, a unit of energy) and constant across all production intensities.

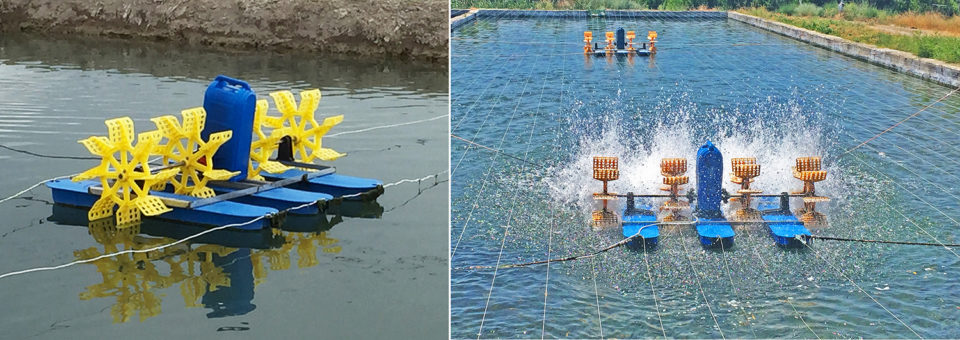

In that location are several types of aerators; different methods of powering aerators; and energy efficiencies of motors, engines and drive trains differ. The experience-based dominion for aerator rate mentioned higher up was developed years ago in Asia for small 1- or 2-hp floating, electric paddlewheel aerators (image 1 beneath) that were widely used in shrimp ponds and for 1- to 2-hp propeller-aspirator-pump aerators (prototype two below) that as well have received observable use in shrimp farming. Over the years, shrimp farmers take learned to fabricate and use less expensive, but also less efficient versions of manufactory-manufactured aerators. A discussion of the factors influencing the efficiency of energy utilisation in shrimp pond aeration is overdue.

Fuels

Aerators frequently are powered by electricity supplied by national or regional grids. Electric generators, usually powered by diesel engines located onsite, may also provide electricity for aeration. Fuels differ in energy content (Table i) and energy also is used to produce these fuels. The total energy use incurred for a fuel is its free energy content plus the corporeality of free energy required for its production (embodied energy). Total energy use may be estimated by multiplying the corporeality of each fuel used by the embodied energy factor for that fuel (Table i).

Boyd, aeration Pt. 1, Tabular array 1

| Fuel | Energy content (i) | Embodied energy cistron |

|---|---|---|

| Ethanol (E100) | 21.27 MJ/L | i.49 (2) |

| Ethanol (E85) | 22.58 MJ/L | i.34 (iii) |

| LPG (liquid propane gas) | 23.48 MJ/L | 1.12 (four) |

| Gasoline (no ethanol) | 31.80 MJ/50 | 1.36 (iv) |

| Gasoline (10% ethanol) | 31.25 MJ/50 | 1.37 (3) |

| Biodiesel | 33.32 MJ/L | 1.69 (5) |

| Diesel (No. two) | 35.lxxx MJ/L | 1.28 (four) |

| Electricity | iii.6 MJ/kWhr | 2.50 |

Table one. Free energy content (lower heating value) of common fuels and factors for including embodied energy in fuel energy calculations.

one: https://afdc.energy.gov/fuels/fuel comparison_chart_pdf.

2: http://big.stanford.edu/courses/2014/ph240/dikeou1/docs/ethanolnetenergy.pdf

3: Calculated.

4: http://www.iea.org/statistics/resources/manuals/

v: https://.adfc.energy.gov/files/pdfs/3229.pdf

The energy contents of a fuel allow conclusion of the volumes of each fuel necessary to provide the same amount of energy at a specific motor or engine efficiency. For instance, 1.68 liters of fuel class ethanol (E100) would be required to obtain the same amount of energy provided by 1.0 liter of No. 2 diesel fuel (35.fourscore MJ/Fifty diesel fuel ÷ 21.27 MJ/L ethanol = 1.68; MJ = megajoule, a unit of energy). Likewise, ix.94 kWhr of electricity represents the same corporeality of energy every bit does ane liter of No. 2 diesel.

Electricity generating plants convert primary energy in coal and other master fuels with an efficiency of around 40 percent, and there is an additional loss of about vii percent of the original primary energy in transmission of electricity through the filigree – an overall efficiency of about 33 percent. Larger generators are more efficient than smaller generators in converting energy of diesel fuel to electricity (Table 2), only larger units are merely 35 to 38 pct efficient, and additional losses will occur in transmission to aerator motors.

Boyd, aeration Pt. 1, Table ii

| Rated output (kW) | Fuel employ at 75% load (L/hr) | Energy output at 75% load (% input) | Energy output at 75% load (kW/L) | Energy output at 75% load (MJ/L) |

|---|---|---|---|---|

| 25 | 7.00 | 26.9 | 2.65 | 9.65 |

| 50 | 13.25 | 28.iv | ii.83 | 10.19 |

| 100 | 21.95 | 34.three | iii.42 | 12.31 |

| 150 | 31.79 | 35.4 | 3.54 | 12.74 |

| 200 | 41.64 | 36.1 | iii.threescore | 12.96 |

| 250 | 51.48 | 36.v | 3.64 | thirteen.10 |

| 500 | 99.92 | 37.6 | 3.75 | 13.50 |

| 750 | 148.75 | 37.nine | 3.78 | xiii.61 |

| 1,000 | 197.xx | 38.1 | 3.80 | 13.68 |

Tabular array 2. Typical fuel apply and free energy output for different sizes of diesel fuel-powered generators.

Source: https://www.dieselserviceandsuply.com/Diesel_Fuel_Consumption.aspx.

Energy efficiency from principal fuel is roughly equal for electricity from the national or regional grid and from onsite generators. The cost of primary fuels per kilowatt-hour generated is less for large power plants than for smaller diesel generators, and filigree electricity usually is less expensive than electricity generated at shrimp farms.

Electric motors

Synchronous consecration, alternating current motors of different types and sizes, are used to power aerators. Smaller electrical motors (i to iii hp) often are unmarried phase and operate on 110-120 volts (V) or 208-230 V, while larger motors unremarkably are three phase and operate on 208-230 V or even 460 V. Motors usually are rated at full load to require a specific current measured in amperes (Table 3); the amperes required double between 115 V and 230 V motors and between 230 V or 460 V motors.

Boyd, aeration Pt. 1, Table 3

| Motor power rating (hp) | Unmarried phase (115 Five) | Single phase (230 Five) | Iii phase (230 V) | 3 phase (460 V) |

|---|---|---|---|---|

| ane | 16 | eight | 3.6 | 1.8 |

| 2 | 24 | 12 | 6.eight | 3.4 |

| 3 | 34 | 17 | 9.6 | four.8 |

| 5 | 56 | 28 | fifteen.2 | 7.6 |

| seven.five | fourscore | forty | 22.0 | eleven.0 |

| ten | 100 | 50 | 28.0 | 14.0 |

| 15 | – | – | 42.0 | 21.0 |

| 20 | – | – | 54.0 | 27.0 |

Tabular array 3. Total-load amperes for single-phase and small, iii-phase electric motors

Source: http://mechreps.com/PDF/MRI_Formulas_Conversions.pdf

The efficiency of electrical motors is calculated as the energy output by the motor shaft (brake power) divided by the energy input to the motor (wire power) equally follows:

kW = Restriction hp × 0.746 ÷ Motor efficiency

The typical efficiencies of small-scale electrical motors are provided in Table 4. Motors should be operated at around 75 percent full load at which service life and efficiency are greater than at full load. A x-hp, 230 5, three-phase motor operated at a brake power of seven.5 hp would use around half-dozen.32 kW or half dozen.32 kW·hr of electricity per 60 minutes.

Boyd, aeration Pt. one, Table iv

| Electric motors | Efficiency (%) | Modest (<25 hp) stationary internal combustion engine | Efficiency (%) |

|---|---|---|---|

| 1-4 hp | 78.8 | Ethanol (E100) | 20-25 |

| 5-ix hp | 84.0 | Liquid propane gas (LPG) | 25-30 |

| 10-19 hp | 85.v | Gasoline | 20-xxx |

| twenty-49 hp | 88.5 | Diesel | 28-32 |

Table four. Efficiencies of pocket-size, electric motors and pocket-sized, stationary internal combustion engines.

Source: https://www.engineering toolbox.com/electrical-motor-efficiency-d_655.html

The amperes of electricity used past a motor is roughly in direct proportion to load between fifty and 100 percentage full load (Fig. ane). The amperes fatigued by an aerator motor can exist easily measured with an ammeter during motor operation and the approximate load estimated. In that location is a substantial no-load current by electric motors, and they waste electricity when substantially under-loaded. The amount of power required to operate paddlewheel aerators increases with greater paddlewheel depth at whatever rotation speed. Attending to the depth of paddle tip submergence is important, because it can alter as the floats for aerators shift during functioning. This results in greater or lesser submergence of paddles which tin can pb to overloading or under-loading of motors.

The rotation speed of electrical motors varies with the number of magnetic poles in the motor (Table 5). Motor slip under-load reduces output shaft speed by 3 to 5 per centum in one to v hp motors and by around 2 to 3 percent in motors of vii.five to 20 hp. Motors for paddlewheel aerators usually take a shaft speed of about 1,735 ppm. By contrast, paddlewheels, depending upon their bore, transfer oxygen nigh efficiently at 80 to 120 rpm. Motors that plough at such low speeds are more expensive, and speed reducers are placed in the drive railroad train of aerators to allow higher speed motors to be used.

Boyd, aeration Pt. 1, Table 5

| Magnetic poles | Electric frequency, 50 Hz | Electric frequency, 60 Hz |

|---|---|---|

| two | 3,000 | iii,600 |

| four | i,500 | 1,800 |

| 6 | one,000 | 1,200 |

| 8 | 750 | 900 |

| 10 | 600 | 720 |

| 12 | 500 | 600 |

| 16 | 375 | 450 |

| twenty | 300 | 360 |

Table five. Electric motor rotation speed every bit related to number of magnetic poles of motor and electrical frequency.

Source: https://www.engineeringtoolbox.com/synchronous-motor-frequency-speed-d_649.html

There likewise is considerable apply of propeller-aspirator-pump aerators in shrimp ponds. Most of these aerators accept ii-pole motors that rotate at about 3,600 rpm (Tabular array 5). This type of aerator does non transfer as much oxygen per unit of measurement of energy if it is supplied with a 4-pole motor. Vertical pump aerators for aquaculture typically are supplied with a four-pole motor.

When electric motors are started up, an inrush of electric current is necessary to start the rotor and advance the shaft to full speed. For unmarried phase motors of 1 to 10 hp, the inrush current is nearly three times the full load motor current requirement in amperes. For three-phase motors, the inrush current is about twice the full load electric current. Large motors usually are started with a motor controller (often chosen a motor starter) with fuses that withstand the big ampere input at start up.

Now that y'all've finished reading the article ...

… we hope you'll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors' expansive noesis every calendar week.

By becoming a Global Seafood Brotherhood fellow member, you're ensuring that all of the pre-competitive piece of work we do through member benefits, resources and events can go on. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Source: https://www.globalseafood.org/advocate/energy-use-in-aquaculture-pond-aeration-part-1/

Posted by: maxeyjact1957.blogspot.com

0 Response to "What Is The Amp Draw On 2016 Power Pole Pump"

Post a Comment